-

ส่งอีเมลถึงเรา

sale@lscmagnetics.com -

เบอร์ติดต่อ

+86 -13559234186

ส่งอีเมลถึงเรา

sale@lscmagnetics.com

เบอร์ติดต่อ

+86 -13559234186

สารขจัดคราบเหล็กเหลว: ผู้พิทักษ์ความต่อเนื่องของการผลิตสารเคมีและคุณภาพของผลิตภัณฑ์อย่างมั่นคง

Aug 21, 2025ในอุตสาหกรรมเคมี ความต่อเนื่องในการผลิตและคุณภาพผลิตภัณฑ์ที่เหนือกว่าคือหัวใจสำคัญของการอยู่รอดและการพัฒนาของบริษัท การหยุดชะงักหรือข้อบกพร่องเล็กๆ น้อยๆ ที่ไม่คาดคิดอาจนำไปสู่ความสูญเสียทางการเงินและความเสี่ยงด้านชื่อเสียงอย่างมาก ในการต่อสู้เพื่อความอยู่รอดที่ไม่มีวันสิ้นสุดนี้ อุปกรณ์สำคัญชิ้นหนึ่งยังคงยืนอยู่แถวหน้าของกระบวนการผลิต เฉกเช่นผู้พิทักษ์ที่เงียบงันและภักดี: น้ำยาล้างเหล็กวันนี้เราจะมาสำรวจว่า "ผู้พิทักษ์" นี้ปกป้องผลประโยชน์หลักของการผลิตสารเคมีสมัยใหม่ที่มีคุณค่าที่ไม่สามารถทดแทนได้อย่างไร

แนวป้องกันแรก: การป้องกันผู้บุกรุกที่มองไม่เห็น

ของเหลวเคมี (วัตถุดิบ สารตัวกลาง และผลิตภัณฑ์สำเร็จรูป) มีความเสี่ยงสูงต่อการปนเปื้อนจากอนุภาคโลหะระหว่างการขนส่งที่ยาวนาน อนุภาคโลหะเหล่านี้มาจากแหล่งที่ซ่อนเร้น:

การสึกหรอของอุปกรณ์: การสึกหรอเรื้อรังของปั๊ม วาล์ว และเครื่องกวน ทำให้เกิดเศษโลหะ

ผลิตภัณฑ์ที่เกิดจากการกัดกร่อน: สนิมและการหลุดลอกจากผนังด้านในของท่อ

วัตถุดิบตกค้าง: สิ่งเจือปนที่มีอยู่ในวัตถุดิบเริ่มต้น

สารตกค้างจากการบำรุงรักษา: เศษโลหะและตะกรันเชื่อมที่เหลืออยู่หลังการซ่อมแซม

อนุภาคโลหะที่มีขนาดไมครอนเหล่านี้ แม้จะดูเหมือนไม่มีนัยสำคัญ แต่ก็เป็นตัวการทำลายล้างที่ร้ายกาจและก่อให้เกิดภัยคุกคามร้ายแรงต่อการผลิตอย่างต่อเนื่องและคุณภาพของผลิตภัณฑ์

บทบาทสำคัญของน้ำยาล้างเหล็กเหลว: จาก "ศูนย์ต้นทุน" สู่ "ศูนย์มูลค่า"

สารขจัดคราบเหล็กเหลวใช้แรงแม่เหล็กแรงสูงเพื่อดูดซับสิ่งสกปรกโลหะเหล่านี้ บทบาทของสารนี้เหนือกว่าแค่การ "กรอง" ธรรมดาๆ และสร้างคุณค่าหลักให้กับธุรกิจโดยตรง:

1. การปกป้องเส้นชีวิตของคุณภาพผลิตภัณฑ์

นี่คือบทบาทที่ตรงที่สุดของสารกำจัดเหล็ก สำหรับสารเคมีคุณภาพสูง เรซินประสิทธิภาพสูง เม็ดสีและสีย้อม วัตถุดิบสำหรับอาหารและยา (เช่น กรดซิตริกและซอร์บิทอล) และสารเคมีสำหรับอิเล็กทรอนิกส์ (เช่น ไฮโดรเจนเปอร์ออกไซด์และกรดซัลฟิวริก) ความบริสุทธิ์ของผลิตภัณฑ์คือหัวใจสำคัญของความสามารถในการแข่งขัน แม้แต่สิ่งเจือปนโลหะในระดับ ppm (ส่วนในล้านส่วน) ก็อาจทำให้เกิด:

2. สีของผลิตภัณฑ์: ไอออนของเหล็กเป็นสารสีที่เข้มข้นซึ่งสามารถทำให้ผลิตภัณฑ์โปร่งใสเปลี่ยนเป็นสีเหลือง และผลิตภัณฑ์สีขาวเปลี่ยนเป็นสีเทา ซึ่งส่งผลกระทบต่อรูปลักษณ์ของผลิตภัณฑ์อย่างรุนแรง

ปฏิกิริยาข้างเคียงของตัวเร่งปฏิกิริยา: โลหะที่เหลือสามารถทำหน้าที่เป็นตัวเร่งปฏิกิริยา ทำให้เกิดปฏิกิริยาออกซิเดชันและพอลิเมอไรเซชันที่ไม่ต้องการในระหว่างการจัดเก็บหรือการใช้งาน ส่งผลให้ผลิตภัณฑ์เสื่อมสภาพและล้มเหลว

การเปลี่ยนแปลงประสิทธิภาพ: สำหรับวัสดุโพลีเมอร์ สิ่งเจือปนของโลหะสามารถส่งผลกระทบอย่างรุนแรงต่อคุณสมบัติทางไฟฟ้า ความแข็งแรงเชิงกล และความโปร่งใส

3. การรับประกันความปลอดภัยและการดำเนินงานระยะยาวของอุปกรณ์การผลิต

อนุภาคโลหะเป็นภัยคุกคามที่มองไม่เห็นต่อสุขภาพของอุปกรณ์ การปกป้องอุปกรณ์หลัก: ปั๊มความเร็วสูง วาล์ววัดความแม่นยำ หัวฉีด และอุปกรณ์อื่นๆ อาจมีรอยขีดข่วนหรือติดขัดจากอนุภาคโลหะแข็ง ทำให้เกิดการสึกหรออย่างรุนแรงและอาจทำให้อุปกรณ์เสียหาย นำไปสู่การหยุดทำงานโดยไม่ได้วางแผนไว้และการสูญเสียที่สำคัญ

การป้องกันพิษจากตัวเร่งปฏิกิริยา: กระบวนการทางเคมีหลายอย่างต้องพึ่งพาตัวเร่งปฏิกิริยาที่มีราคาแพง (เช่น ตัวเร่งปฏิกิริยา Pd และ Pt) เหล็กเจือปนสามารถปกคลุมบริเวณที่ออกฤทธิ์ของตัวเร่งปฏิกิริยา ทำให้เกิดพิษและหมดฤทธิ์อย่างถาวร ส่งผลให้ต้นทุนการผลิตเพิ่มสูงขึ้นอย่างมาก

การกำจัดอันตรายด้านความปลอดภัย: ในกระบวนการผลิตที่เกี่ยวข้องกับแรงดันสูง อุณหภูมิสูง หรือวัสดุไวไฟและวัตถุระเบิด แรงเสียดทานของอนุภาคโลหะอาจทำให้เกิดประกายไฟ ซึ่งก่อให้เกิดความเสี่ยงด้านความปลอดภัยอย่างมีนัยสำคัญ ตัวแยกแม่เหล็กสามารถกำจัดอันตรายนี้ได้อย่างมีประสิทธิภาพ

4. การประหยัดพลังงานและลดการใช้พลังงาน เพิ่มประสิทธิภาพทางเศรษฐกิจ

การลดเศษวัสดุ: การกำจัดผลิตภัณฑ์ที่มีเหล็กชำรุดอย่างมีประสิทธิภาพช่วยลดการสูญเสียคุณภาพและต้นทุนการทำงานซ้ำโดยตรง

การยืดอายุการใช้งานอุปกรณ์: การสึกหรอของอุปกรณ์ที่ลดลงช่วยลดความถี่ในการบำรุงรักษาและต้นทุนการจัดหาชิ้นส่วนอะไหล่

การปกป้องตัวเร่งปฏิกิริยา: การยืดอายุการใช้งานของตัวเร่งปฏิกิริยาจะช่วยประหยัดเงินได้มากกว่าการลงทุนในตัวแยกแม่เหล็กมาก

ลดการใช้พลังงาน: ของเหลวที่สะอาดจะช่วยลดแรงต้านทานในการส่ง ช่วยลดการใช้พลังงานในการสูบ

การประยุกต์ใช้ตัวแยกแม่เหล็กแทรกซึมไปทั่วทั้งวงจรการผลิตสารเคมี ตำแหน่งการติดตั้งไม่ได้ถูกกำหนดขึ้นโดยพลการ แต่ขึ้นอยู่กับความเข้าใจอย่างลึกซึ้งในกระบวนการและการประเมินจุดเสี่ยงที่อาจเกิดขึ้นอย่างแม่นยำ ในการออกแบบสารเคมีสมัยใหม่ ตัวแยกแม่เหล็กได้พัฒนาจาก "ส่วนประกอบเสริม" มาเป็นคุณสมบัติมาตรฐานหลักที่รับประกันความปลอดภัย คุณภาพ และประสิทธิภาพ

| แอปพลิเคชัน | วัตถุประสงค์หลัก | ตัวอย่างของสื่อของเหลวทั่วไป |

| การเตรียมวัตถุดิบเบื้องต้น | ควบคุมทางเข้าให้เข้มงวดเพื่อป้องกันการปนเปื้อนจากภายนอก | น้ำที่ใช้ในกระบวนการ ตัวทำละลาย กรด น้ำซึมแร่ น้ำเชื่อม สารละลายแป้ง |

| ปฏิกิริยาและการเร่งปฏิกิริยา | ปกป้องตัวเร่งปฏิกิริยาและบำรุงรักษาเครื่องปฏิกรณ์ | สารละลายตัวเร่งปฏิกิริยา วัสดุปฏิกิริยาหมุนเวียน โมโนเมอร์พอลิเมอไรเซชัน |

| การแปรรูปผลิตภัณฑ์ขั้นกลาง | รับรองความสะอาดระหว่างกระบวนการและปกป้องอุปกรณ์การกลั่น | ของเหลวก่อนการกรอง, การป้อนเรซินแลกเปลี่ยนไอออน, การป้อนเครื่องระเหย |

| การกลั่นผลิตภัณฑ์ขั้นสุดท้าย | รับประกันคุณภาพโรงงานเพื่อตอบสนองความต้องการระดับไฮเอนด์ | สารเคมีเกรดอิเล็กทรอนิกส์ ผลิตภัณฑ์เกรดเภสัชกรรม เรซินระดับไฮเอนด์ น้ำมันหล่อลื่นรีไซเคิล |

จะเพิ่มประสิทธิภาพการเลือกและการใช้งานได้อย่างไร?

การเพิ่มประสิทธิภาพสูงสุดของน้ำยาขจัดคราบเหล็ก การเลือกและการใช้ที่ถูกต้องถือเป็นสิ่งสำคัญ:

1. การเลือกที่แม่นยำคือกุญแจสำคัญ:

ลักษณะของวัสดุ: พิจารณาความหนืดของของเหลว อุณหภูมิ ค่า pH และฤทธิ์กัดกร่อนเพื่อเลือกอุปกรณ์ที่มีวัสดุที่เหมาะสม (เช่น สแตนเลส 304/316L หรือ Hastelloy) และประเภทของการปิดผนึก

ลักษณะของสิ่งเจือปน: วิเคราะห์ขนาด เนื้อหา และคุณสมบัติทางแม่เหล็ก (แรง/อ่อน) ของอนุภาคสิ่งเจือปนเพื่อกำหนดความเข้มข้นของแม่เหล็กที่ต้องการ (ค่าเกาส์) และการไล่ระดับ

อัตราการไหลและแรงดันในท่อ: เลือกคุณลักษณะที่ตรงกับท่อหลักเพื่อลดการลดลงของแรงดันและป้องกันการหยุดชะงักของการผลิตตามปกติ

2. ประเภทอุปกรณ์ที่ต้องการ:

แม่เหล็กถาวร: ประหยัดพลังงานและไม่ต้องบำรุงรักษา มีแรงแม่เหล็กที่ยาวนาน เหมาะสำหรับการใช้งานส่วนใหญ่ที่เกี่ยวข้องกับการกำจัดสิ่งสกปรกที่มีแม่เหล็กแรงสูง

แม่เหล็กไฟฟ้า: แรงแม่เหล็กที่ปรับและสลับได้ ช่วยให้ทำความสะอาดอัตโนมัติได้ง่ายขึ้น เหมาะสำหรับการใช้งานที่มีสิ่งเจือปนสูงหรือต้องการการทำความสะอาดบ่อยครั้ง อย่างไรก็ตาม วิธีนี้ใช้พลังงานมากกว่า

3. จัดทำระบบบำรุงรักษาเชิงวิทยาศาสตร์:

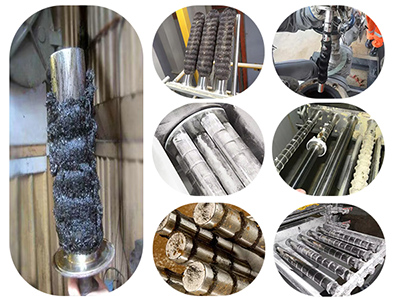

ทำความสะอาดแท่งแม่เหล็กหรือแผ่นแม่เหล็กเป็นประจำตามปริมาณสิ่งเจือปน เพื่อป้องกันไม่ให้มีชั้นสิ่งเจือปนหนาๆ ที่จะส่งผลต่อการดูดซับหรือถูกชะล้างออกไปโดยของเหลว

รวมการทำความสะอาดและการตรวจสอบน้ำยาขจัดคราบเหล็กไว้ในโปรแกรมการตรวจสอบและการบำรุงรักษาเชิงป้องกัน (PM) ประจำวันของคุณ