-

ส่งอีเมลถึงเรา

sale@lscmagnetics.com -

เบอร์ติดต่อ

+86 -13559234186

ส่งอีเมลถึงเรา

sale@lscmagnetics.com

เบอร์ติดต่อ

+86 -13559234186

จะเลือกแม่เหล็กคอนกรีตสำเร็จรูปให้เหมาะกับโครงการของคุณได้อย่างไร?

Aug 08, 2025ด้วยการพัฒนาอย่างรวดเร็วของการก่อสร้างแบบสำเร็จรูป แม่เหล็กคอนกรีตสำเร็จรูป ได้กลายเป็น "ฮีโร่ที่มองไม่เห็น" ของไซต์ก่อสร้างสมัยใหม่ อุปกรณ์แม่เหล็กที่ดูเหมือนเรียบง่ายเหล่านี้ แท้จริงแล้วเป็นเครื่องมือสำคัญที่ช่วยให้มั่นใจถึงตำแหน่งที่แม่นยำของแบบหล่อและเพิ่มประสิทธิภาพในการก่อสร้าง อย่างไรก็ตาม ด้วยแม่เหล็กหลากหลายประเภทและคุณสมบัติที่มีอยู่ในท้องตลาด คุณจะเลือกผลิตภัณฑ์ที่ดีที่สุดสำหรับโครงการของคุณได้อย่างไร

เหตุใดการเลือกแม่เหล็กจึงมีความสำคัญมาก?

แม่เหล็กคอนกรีตสำเร็จรูป ซึ่งใช้แรงดึงดูดแม่เหล็กแรงสูงแทนวิธีการเชื่อมและยึดด้วยสลักเกลียวแบบดั้งเดิม ได้ปฏิวัติการติดตั้งแบบหล่อ แม่เหล็กเหล่านี้ยึดแบบหล่อเหล็กเข้ากับแท่นหรือคานได้อย่างแน่นหนาภายในไม่กี่วินาที ไม่จำเป็นต้องเจาะและป้องกันความเสียหายที่อาจเกิดขึ้นกับแท่นแบบหล่อ ช่วยยืดอายุการใช้งานของแบบหล่อได้มากกว่า 30% ที่สำคัญ แม่เหล็กเหล่านี้สามารถนำกลับมาใช้ซ้ำได้หลายพันครั้ง ช่วยลดต้นทุนแรงงานและการสูญเสียวัสดุได้อย่างมาก อย่างไรก็ตาม การเลือกใช้งานที่ไม่เหมาะสมอาจนำไปสู่ปัญหาการเคลื่อนตัวของแบบหล่อ คอนกรีตรั่วซึม และอาจถึงขั้นเกิดอุบัติเหตุด้านความปลอดภัยได้

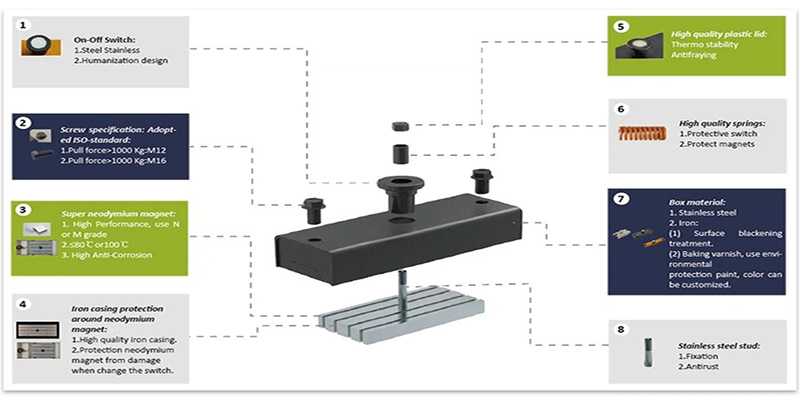

ส่วนประกอบหลักของแม่เหล็กคอนกรีตสำเร็จรูป

1. ตัวเรือนเหล็ก

ตัวเรือนทำจากเหล็กกล้าความแข็งแรงสูง ทนทานต่อการกัดกร่อน ช่วยปกป้องแม่เหล็กจากแรงกระแทก ความชื้น และสารเคมี ซึ่งเป็นสิ่งสำคัญอย่างยิ่งสำหรับการใช้งานในระยะยาวในสภาพแวดล้อมการก่อสร้างที่มีความต้องการสูง ตัวเรือนที่ได้รับการออกแบบอย่างดีจะช่วยให้มีแรงยึดที่สม่ำเสมอและอายุการใช้งานที่ยาวนานขึ้น

2. แกนนีโอไดเมียม

แกนกลางของแม่เหล็กสำเร็จรูปแต่ละชิ้นทำจากแม่เหล็กนีโอไดเมียมธาตุหายาก ซึ่งขึ้นชื่อเรื่องพลังยึดเกาะที่เหนือกว่า แม่เหล็กนีโอไดเมียมแตกต่างจากแม่เหล็กเฟอร์ไรต์ตรงที่มีขนาดกะทัดรัดและมีความหนาแน่นของแรงสูง จึงมั่นใจได้ถึงการยึดเกาะที่มั่นคงแม้ภายใต้แรงสั่นสะเทือนหรือแรงกดทับจากแบบหล่อที่มีน้ำหนักมาก

3. ปล่อยคันโยกหรือปุ่ม

ระบบปลดแบบกลไกในตัว (โดยทั่วไปจะเป็นคันโยกหรือปุ่ม) ช่วยให้ติดตั้งและถอดได้อย่างรวดเร็วโดยไม่ต้องใช้เครื่องมือ คุณสมบัตินี้ช่วยเพิ่มประสิทธิภาพ ลดความเมื่อยล้า และลดความเสี่ยงที่แบบหล่อจะวางไม่ตรงแนว

ปัจจัยการเลือกหลักสี่ประการ

1. ความแข็งแกร่งของแม่เหล็กและความต้องการโหลด (แกนกลางของแกนกลาง)

- การใช้งานสำหรับงานเบา (กรอบหน้าต่าง แผงผนังขนาดเล็ก): เลือกแม่เหล็กที่มีพิกัดรับน้ำหนักได้ 900 กก. เช่น กล่องแม่เหล็กขนาดกะทัดรัด

- การใช้งานระดับปานกลาง (แผงผนังมาตรฐาน, แบบหล่อเสา): แม่เหล็กที่มีพิกัดรับน้ำหนัก 1,350-1,800 กก. ถือเป็นตัวเลือกที่ดีที่สุด

- การใช้งานที่ต้องใช้งานหนัก (พื้นแผ่นใหญ่ ส่วนประกอบสะพาน): แม่เหล็กที่มีพิกัดรับน้ำหนัก 2,100 กก. ขึ้นไปมีความจำเป็น เช่น แม่เหล็กที่ใช้ในระบบแบบหล่องานหนัก

2. จับคู่ประเภทแม่เหล็กกับสถานการณ์การใช้งาน

| ประเภทของแม่เหล็ก | สถานการณ์การใช้งานที่ดีที่สุด | ข้อได้เปรียบที่เป็นเอกลักษณ์ | ผลิตภัณฑ์ทั่วไป |

| กล่องแม่เหล็กแม่แบบ | แผงคอมโพสิต แผงผนังขนาดเล็ก | โครงสร้างเรียบง่ายและประสิทธิภาพต้นทุนสูง | กล่องแม่เหล็กฐาน 600-800 กก. |

| แม่เหล็กแบบขั้นบันได | แม่พิมพ์ด้านสูง ชิ้นส่วนรูปทรงพิเศษ | การออกแบบป้องกันการลื่น ปรับให้เข้ากับขอบที่ไม่เรียบได้ | แม่เหล็กขั้นบันไดแบบกำหนดเอง |

| แม่เหล็กแม่แบบมุม | ข้อต่อคาน-เสา มุมผนัง | การยึดที่แม่นยำ 90 องศา แม่พิมพ์ป้องกันการระเบิด | แม่เหล็กมุมเสริมแรง |

| แถบแม่เหล็กลบมุม | ขอบแผงผนัง เส้นตกแต่ง | มีความยืดหยุ่นและโค้งงอได้ ทำให้มีมุมเอียง 45 องศาที่แม่นยำ | แถบแม่เหล็กยาง |

| แม่เหล็กปลั๊กอิน | การยึดชิ้นส่วนฝังตัวและท่อ | ด้วยการเชื่อมต่อแบบเกลียว การวางตำแหน่งที่แม่นยำ | ฝาครอบยางพร้อมแม่เหล็กฝัง |

| ระบบเทมเพลตแม่เหล็ก | สายการผลิตแผงผนังขนาดใหญ่ | รางนำทางแบบบูรณาการเพื่อการประกอบและถอดประกอบอย่างรวดเร็ว | ระบบถ้วยดูดพร้อมรางเหล็ก |

โซลูชันสำหรับสถานการณ์พิเศษ:

- พื้นผิวโค้ง: ใช้แม่เหล็กกลมหรือแถบแม่เหล็กลบมุมแบบยืดหยุ่น

- เทมเพลตยาวพิเศษ: แม่เหล็กแบบแถบให้แรงดึงดูดที่ต่อเนื่องและสม่ำเสมอ

- สภาพแวดล้อมการบ่มด้วยไอน้ำอุณหภูมิสูง: ต้องใช้แม่เหล็กนีโอไดเมียมที่ทนทานต่ออุณหภูมิสูงที่ผลิตเป็นพิเศษ (อุณหภูมิในการทำงาน >80°C)

3. ปัจจัยด้านสิ่งแวดล้อมและการดำเนินงาน

- ความไวต่ออุณหภูมิ: แม่เหล็กนีโอไดเมียมทั่วไปจะเริ่มสลายสภาพแม่เหล็กเมื่ออุณหภูมิสูงกว่า 80°C ต้องใช้แม่เหล็กที่ทนอุณหภูมิสูงใกล้กับเตาเผาไอน้ำ

- สภาพพื้นผิว: สนิม น้ำมัน หรือคราบคอนกรีต สามารถลดแรงแม่เหล็กได้ถึง 40% โปรดตรวจสอบให้แน่ใจว่าพื้นผิวสัมผัสเรียบ

- การป้องกันการกัดกร่อน:

- ตัวเรือนสแตนเลสเป็นที่นิยมสำหรับสภาพแวดล้อมที่มีความชื้น (แม้ว่าต้นทุนจะสูงกว่า 30% แต่อายุการใช้งานเพิ่มขึ้นเป็นสองเท่า)

- โครงเหล็กกล้าคาร์บอนที่มีความแข็งแรงสูงเหมาะสำหรับสถานที่แห้ง (เป็นตัวเลือกที่คุ้มต้นทุน)

- ระยะขอบความปลอดภัย: แรงโหลดจริงไม่ควรเกิน 70% ของค่าพิกัดของแม่เหล็ก ควรเพิ่มระยะขอบความปลอดภัยอีก 30% สำหรับสภาวะการสั่นสะเทือน

4. เกณฑ์ทองคำสำหรับ การเลือกซัพพลายเออร์

- การรับรอง: ให้ความสำคัญกับผู้ผลิตที่มีใบรับรอง ISO 9001 และ CE

- การสนับสนุนด้านวิศวกรรม: ซัพพลายเออร์ที่ให้บริการจำลองแม่เหล็กและบริการการว่าจ้างในสถานที่สามารถลดความเสี่ยงในการเลือกได้

- ความสามารถในการปรับแต่ง: สำหรับโครงการพิเศษ (เช่น ส่วนประกอบที่มีรูปร่างพิเศษ) ให้เลือกผู้ผลิตที่รองรับการผลิตแบบกำหนดเอง

คู่มือการเลือกตามสถานการณ์

1. การผลิตแผงคอมโพสิตสำหรับที่พักอาศัย: แนะนำให้ใช้ตลับแม่เหล็กขนาด 600-800 กก. ห่างกัน 1-1.5 เมตร ซึ่งให้ประสิทธิภาพด้านต้นทุนที่เหมาะสมที่สุด และช่วยให้สามารถวางตำแหน่งโหมดเดียวได้ภายใน 30 วินาที จึงเหมาะอย่างยิ่งสำหรับการผลิตสำหรับหลายครอบครัว

2. สายการผลิตแผงผนังขนาดใหญ่: เหมาะสำหรับตลับแม่เหล็ก 1,350 กก. และระบบรางนำแม่เหล็ก – เหมาะสำหรับการใช้งานโต๊ะสั่นสะเทือน ช่วยให้เปลี่ยนแบบหล่อได้ภายใน 5 นาทีเมื่อใช้ร่วมกับเครน

3. การผลิตชิ้นส่วนรูปทรงพิเศษ (คานคู่ T, ซุ้มประตู): แนะนำให้ใช้: แม่เหล็กแบบขั้นบันไดและแม่เหล็กรูปตัว U ร่วมกัน – ยึดพื้นผิวโค้งที่ซับซ้อนได้อย่างแม่นยำ โครงการในประเทศจีนประสบความสำเร็จในการนำโซลูชันนี้ไปใช้ ช่วยลดการเคลื่อนตัวของแบบหล่อได้ถึง 90%

4. พื้นที่อุณหภูมิสูง/สภาพแวดล้อมการบ่มด้วยไอน้ำ: แกนนีโอไดเมียมที่ทนต่ออุณหภูมิสูง (อุณหภูมิการทำงาน 150°C) + ตัวเรือนปิดผนึกสแตนเลส – ป้องกันการดริฟท์ของแบบหล่อที่เกิดจากการลดทอนแม่เหล็ก

กฎทองสำหรับการบำรุงรักษาและความปลอดภัย

สามขั้นตอนในการยืดอายุ:

1. การดูแลประจำวัน: ใช้ที่ขูดสเตนเลสเพื่อขจัดเศษวัสดุออกจากพื้นผิวแม่เหล็ก หลีกเลี่ยงการใช้เครื่องมือเหล็ก เพราะเศษเหล็กจะถูกดูดติดแม่เหล็ก สำหรับคอนกรีตที่แข็งตัวหรือมีคราบฝังแน่น ให้ใช้เครื่องขัดที่มีแผ่นขัดลวดเพื่อคืนความเรียบเนียนและสัมผัสที่สมบูรณ์

2. เคล็ดลับในการจัดเก็บ: หลังการใช้งาน ควรทำความสะอาดแม่เหล็กและเก็บในรถเข็นที่ไม่ใช่เหล็ก (สแตนเลส) เพื่อป้องกันการติด หลีกเลี่ยงการเก็บแม่เหล็กบนพื้นผิวเหล็ก เพราะอาจทำให้ถอดออกยากและเกิดความเสียหายโดยไม่ได้ตั้งใจ

3. การตรวจสอบเป็นประจำ: ทดสอบทุกเดือนด้วยเครื่องวัดสนามแม่เหล็กแบบพกพา เปลี่ยนทันทีหากค่าการลดทอนเกิน 15%

แนวทางความปลอดภัย:

- ผู้ที่สวมเครื่องกระตุ้นหัวใจต้องเว้นระยะห่างอย่างน้อย 3 เมตร

- ห้ามบรรทุกเกินพิกัดโดยเด็ดขาด จำเป็นต้องมีการเสริมแรงเพิ่มเติมภายใต้สภาวะการสั่นสะเทือน

- เมื่อถอดแบบหล่อ ให้ถอดแม่เหล็กออกก่อนงัดแบบหล่อ เพื่อหลีกเลี่ยงความเสียหายจากแรงกระแทกต่อแกนแม่เหล็ก

การเลือกแม่เหล็กคอนกรีตสำเร็จรูปไม่ใช่เรื่องง่าย ๆ เพียงแค่เลือกแม่เหล็กที่แข็งแรงที่สุด แต่เป็นกระบวนการที่เป็นระบบซึ่งต้องพิจารณาอย่างถี่ถ้วนถึงคุณลักษณะของโครงการ ความต้องการรับน้ำหนัก ปัจจัยด้านสิ่งแวดล้อม และการทำงานร่วมกันเป็นทีม การเลือกที่แม่นยำสามารถเพิ่มประสิทธิภาพการก่อสร้างได้ 50% พร้อมลดความผิดพลาดในการวางแบบหล่อให้เหลือเพียงระดับมิลลิเมตร